Metering Screw Feeders

Principle and Operation

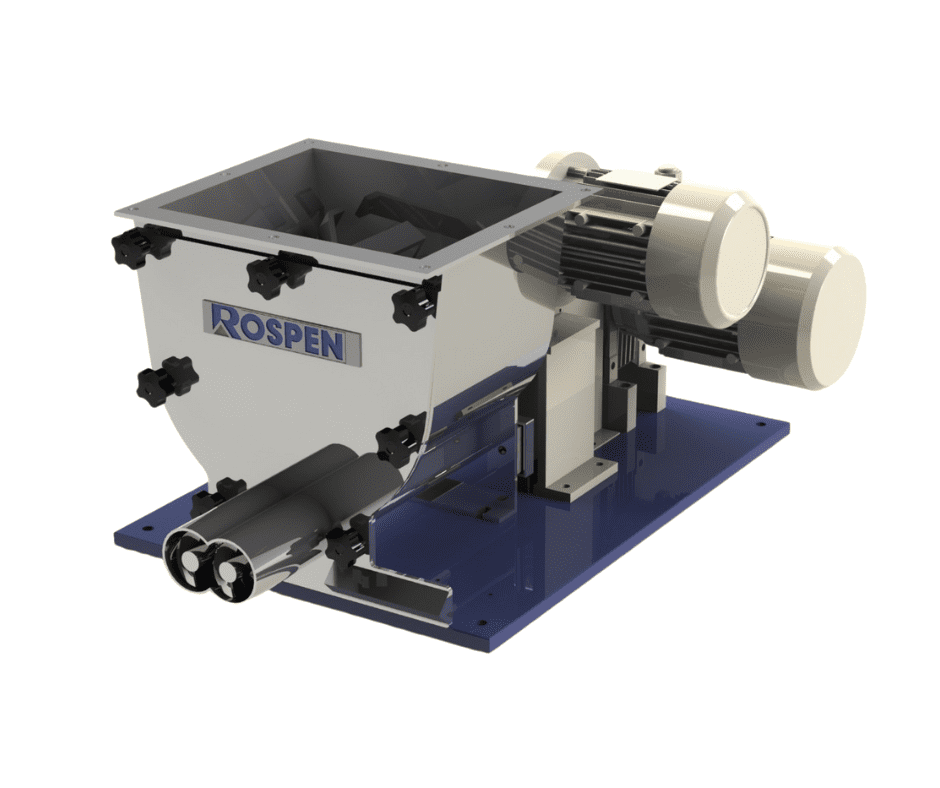

In response to specific customer requirements across the spectrum of industry, Rospen Industries have developed their successful range of Metering Screw Feeders to encompass special designs that are both industry sector and material specific. Whatever the feeder type the result is the continuous metering of all materials from flushing powders to fibrous particulate products at a constant volume to high accuracies. Based on the benefits of the Rospen, Metering Screw Feeder principle, one such machine is the Multi Agitator Feeder.

Multi Agitator Feeders

Designed with a very large inlet area of 0.25 sq.m to allow the fitting of a large outlet hopper. Also incorporated are two, full length independently driven twin shaft agitator product conditioners, which continuously sweep the conditioning chamber.

The very active live hopper outlet feature allows the feeder to handle difficult products, which may bridge, stick or rat hole, such as cooked cereals. The agitators can be wired to counter-rotate or co-rotate to suit the application and a speed inverter can be fitted to allow different conditioning rates.

Single Screw Feeders

Principle and Operation

Metering Screw Feeder is also known as Volumetric Feeder is designed to continuously meter all materials from flushing powders to fibrous particulate products at a constant volume to high accuracies. The basic feeder consists of a Rospen designed, unique tapered conditioning chamber, complete with a slow rotation agitator and variable control functions, which provides constant or intermittent operation, to suit the nature of the products being handled.

Twin Screw Feeders

Metering Screw Feeder is also known as Volumetric Feeder is designed to continuously meter all materials from flushing powders to fibrous particulate products at a constant volume to high accuracies. The basic feeder consists of a Rospen designed, unique tapered conditioning chamber, complete with a slow rotation agitator and variable control functions, which provides timed on /off settings, constant or intermittent operation, to suit the nature of the products being handled.

Special Designs

In response to specific customer requirements Rospen can also provide;

- Variable geometry; pitch, core thickness, flight diameter

- Ribbon type

- Reversing type

- Centerless auger

- Specialist coatings; tungsten carbide, PTFE/li>

- Specialist materials; hardox, duplex/li>

We’d love to hear from you

Fill in the form and a member of the team will be in touch

![Image 1 – MSF50[14]](https://b4133931.smushcdn.com/4133931/wp-content/uploads/2023/12/Image-1-MSF5014.jpg?lossy=2&strip=0&webp=1)